Since 2005, we have worked closely with Praxair Mexico to provide control solutions for stationary CO₂ tanks. Control panels for different types of tanks and customers have been developed and manufactured since then up to the present day. The tanks can be horizontal, where the volume is measured using a load cell system to know the weight of the product inside the tank, and there are also vertical tanks, where the volume is detected through differential pressure. For both types of tanks, it is common to have cooling systems used to reduce pressure within the tank. In terms of customer type, it is divided into high-consumption customers, usually from the beverage and food industry, and low-consumption customers where CO₂ is used for auxiliary services such as fire suppression systems or some other processes.

To meet this variety of requirements, several versions were designed:

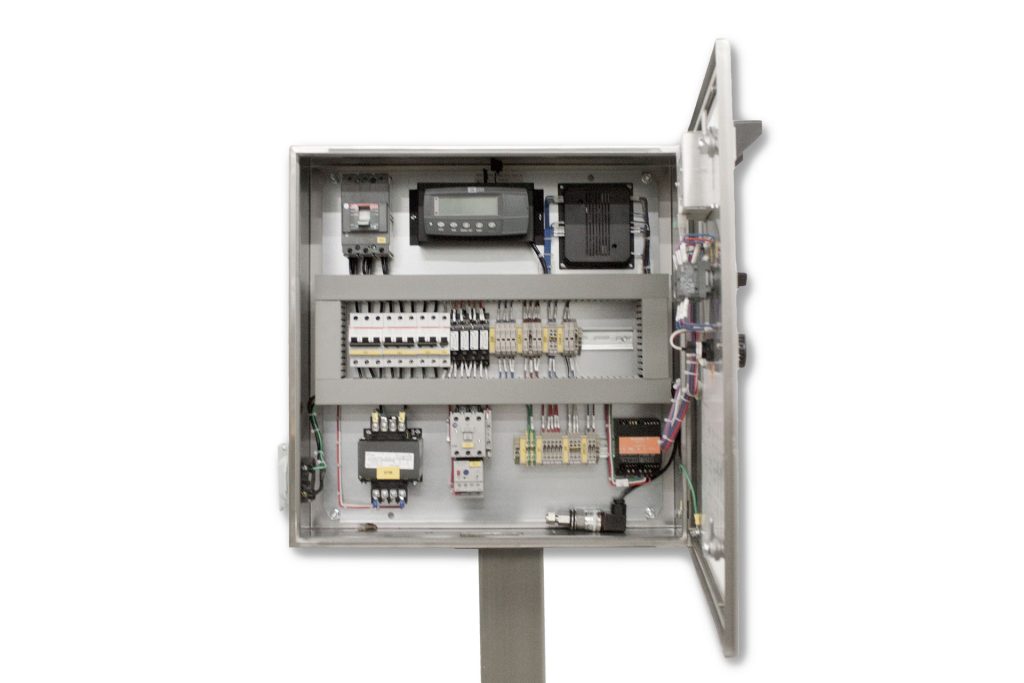

The basic version for horizontal tanks mounted on load cells is the TTU panel. This system controls key process components such as valves, compressors, pressure relief mechanisms, and heating elements, in order to control the tank pressure and ensure safe operation. This system includes a digital scale that reads the signal from the load cell via serial communication, allowing for high-resolution measurement.

The premium version for horizontal tanks is the TTP panel, which not only controls the operation of the process but also has cellular telemetry to send weight and pressure data in the tank in real-time, as well as real-time alerts via SMS or email and daily reports with tank level information. All of this is used to schedule tank filling services and maintenance.

The version for vertical tanks is the TTU panel, this panel controls the key components of the installation such as valves, compressors, pressure relief mechanisms, and heating elements, in order to maintain the optimal tank pressure and ensure safe operation. This panel does not have the option to record the weight of the tank.

Main Features:

- Automatic tank pressure regulation

- On-site configuration of thresholds and alarm settings

- Level monitoring using weight or differential pressure

- LED display for clear readings in day or night conditions

- Optional remote telemetry and alarm notifications

- IP65-rated stainless steel enclosure for outdoor durability

Operational Capabilities:

The panel automatically control the tank pressure by operation of components such as:

- Liquid/gas phase valves

- Refrigeration compressors

- Pressure accumulation valves

- Heaters (if available in the facility)

Local alarms are activated when parameters fall outside established thresholds. These alarms, along with operational data, are displayed on an integrated HMI screen. Operators can also use the interface to set operational and alarm limits directly on site.