Real time operational intelligence for the Glass Industry

In 2012 our client, a major manufacturer in the glass industry with operations in Mexico and the United States, faced the complex challenge of managing and optimizing operations across multiple plant types, specifically glass container and flat glass production facilities.

SIOS implemented a PI System as the core infrastructure for data acquisition, visualization, and analysis. The project was executed in stages, adapting the implementation to each plant’s needs and operating conditions. Key components of the solution included:

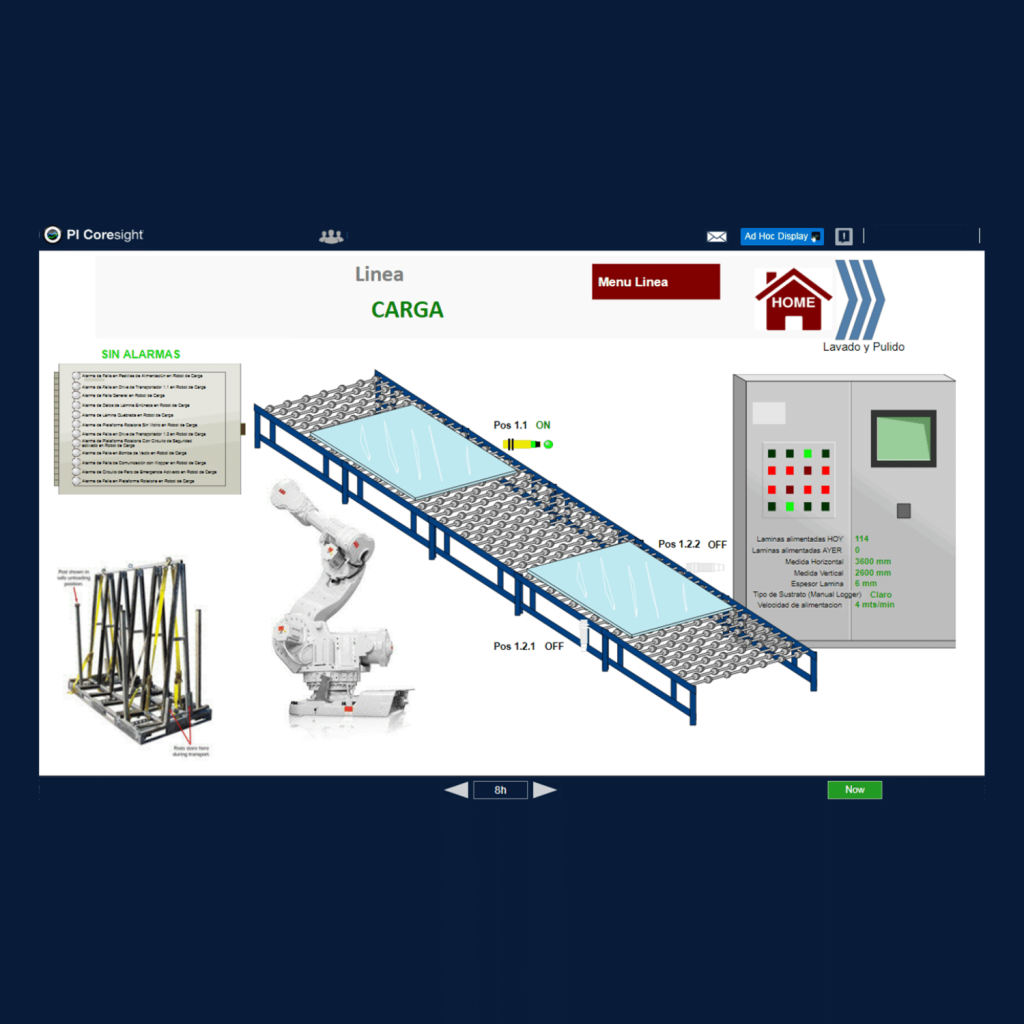

* Dashboards and overview screens tailored for glass container and flat glass processes

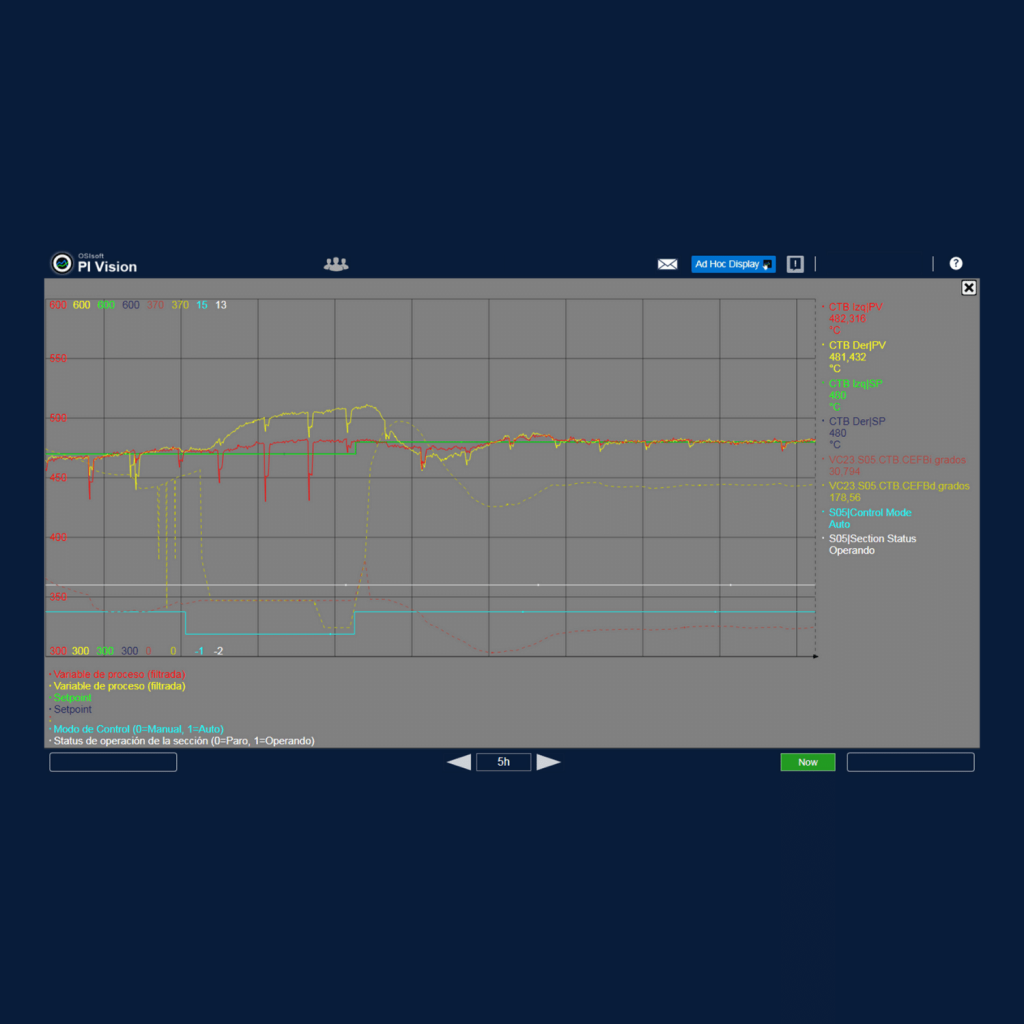

* Real-time monitoring of critical variables, energy consumption, and totalizers

* Batch-based production and quality reporting, allowing traceability and performance comparison

* Energy monitoring tools for consumption tracking, power quality, and efficiency analysis

* Continuous integration of process condition analytics to identify optimal operation parameters

The Benefits

* Full operational visibility across all plants and production types

* Improved production consistency through batch analysis and KPI tracking

* Energy efficiency insights, supporting sustainability and cost reduction goals

* Data-driven decision-making enabled by real-time and historical data

* Standardization of best practices, replicable across multiple sites

* Scalable system architecture, supporting ongoing digital transformation

Currently, the system is fully deployed across all the client’s plants in Mexico, USA and Europe, with ongoing enhancements focused on advanced analytics and predictive optimization enabling the client to extract maximum value from their operational data.