In 2024, we participated in a project with one of our clients in the food industry. The client was looking for a solution to automatically collect the weight of the dough balls, by production line and by row. These weights were manually checked on the rounding/dividing machines by the operator on a digital scale, but the result of each measurement was recorded on production sheets without being entered into PI System (the plant information system).

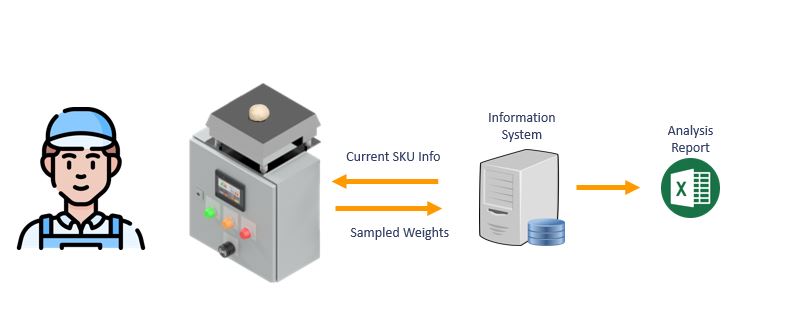

For this case, a specialized solution was developed using a digital scale with serial communication, a microcontroller, and an HMI. Through these components, the data registered on the scale can be read digitally and pushed directly to the PI Server records using the PI SDK. Data is also displayed to the operator on the HMI, including any deviations. The HMI is also used to guide the operator through visual and auditory signals, indicating when to perform the weighing sequence and from which row the dough ball should be taken to be weighed.

This solution addresses the root problems associated with human errors in the manual data collection and also provides visual assistance to correct detected deviations in real time, helping to keep the product weight within the defined specifications. This process ensures the consistency of the information and minimizes human error.

The system communicates directly with the PI System to obtain the active product specifications, including target weight and upper and lower limits. As the operator records the weight of each ball of dough using the integrated scale, the system immediately validates whether it is within the defined thresholds. This allows for early detection of mechanical deviations.

If a reading is found outside acceptable limits, real-time alerts are activated so the operator can take immediate corrective action.

Each recorded weight is sent to the plant’s PI System, along with metadata such as the timestamp, machine, row number, and product ID. This historical information allows:

- Identify weight trends

- Detect irregularities in the Rounder/Divider machine

- Early detection of maintenance issues when weight variations suggest mechanical problems.

Key Benefits:

- Full traceability: each weight logged with date, time, row, and machine ID

- Automated comparison against product weight specs

- Real-time alerts for out-of-spec dough balls

- Light and buzzer guide the operator during weighing sequences

- Adjustable interval between weighing cycles by supervisor

- Data-driven condition-based maintenance based in per-row behavior