The client operated four production lines with PLCs dedicated to the automotive battery manufacturing process. However, they lacked a centralized platform that would allow them to monitor production in real time, compare performance across lines and shifts, analyze historical process trends, and generate operational reports quickly.

This lack of visibility hindered timely decision-making and consistent monitoring of key performance indicators.

Although production data was being generated, it had several limitations:

- The information was neither centralized nor available for comparative analysis.

- Report generation depended on manual processes or local access.

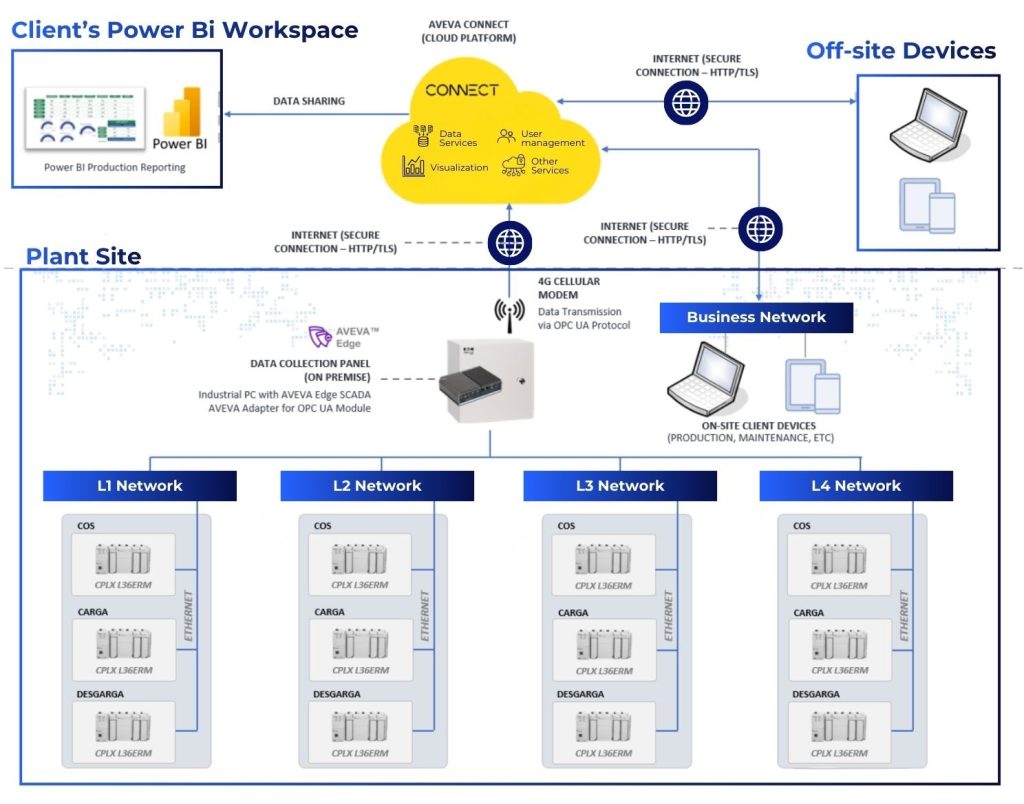

Additionally, the technical environment also presented some significant restrictions for implementing a data integration solution:

- Due to IT security policies, it was not possible to use the plant’s internal network.

- Some lines shared duplicate IP addresses, preventing traditional integration.

To address these restrictions, SIOS designed and implemented a hybrid architecture that combined local processing and cloud services without modifying the client’s existing infrastructure.

The solution included:

- AVEVA Edge SCADA, installed on-site for real-time data capture and processing

- AVEVA Adapter for OPC UA, for data acquisition from PLCs

- LTE cellular modem, enabling secure data transmission without using the plant network

- AVEVA Connect, as a central cloud platform for data consolidation, visualization, and management

- Power BI, for generating operational and comparative reports

All communication was conducted via secure HTTP/TLS connections, ensuring data integrity and confidentiality.

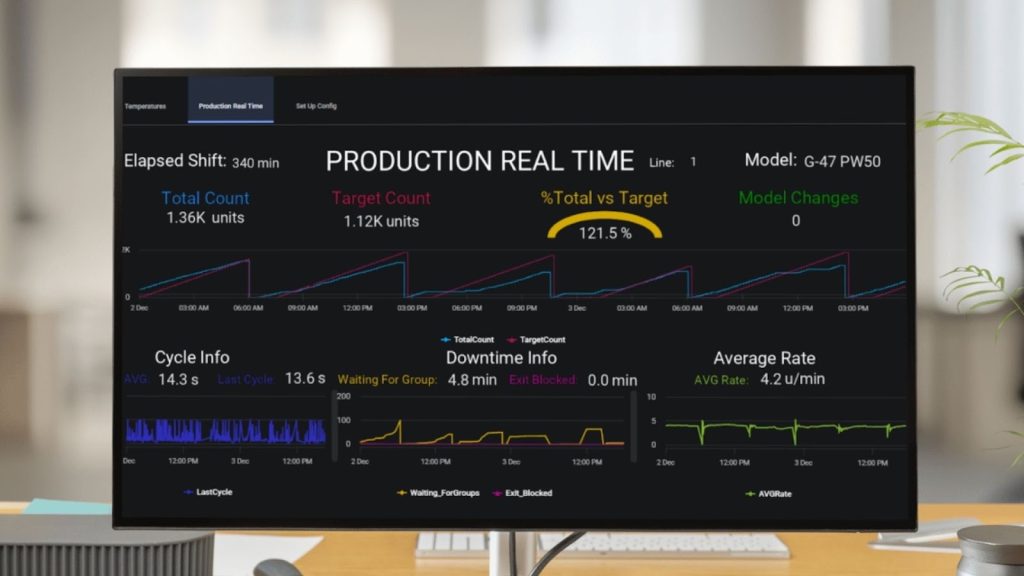

With this architecture, the client gained access to key information such as:

- Scheduled vs. actual production

- Differences by line and shift

- Percentage of performance

- Average cycle time

- Average production rate

- Model changes

- Start and end times of operation

- Downtime classified by cause

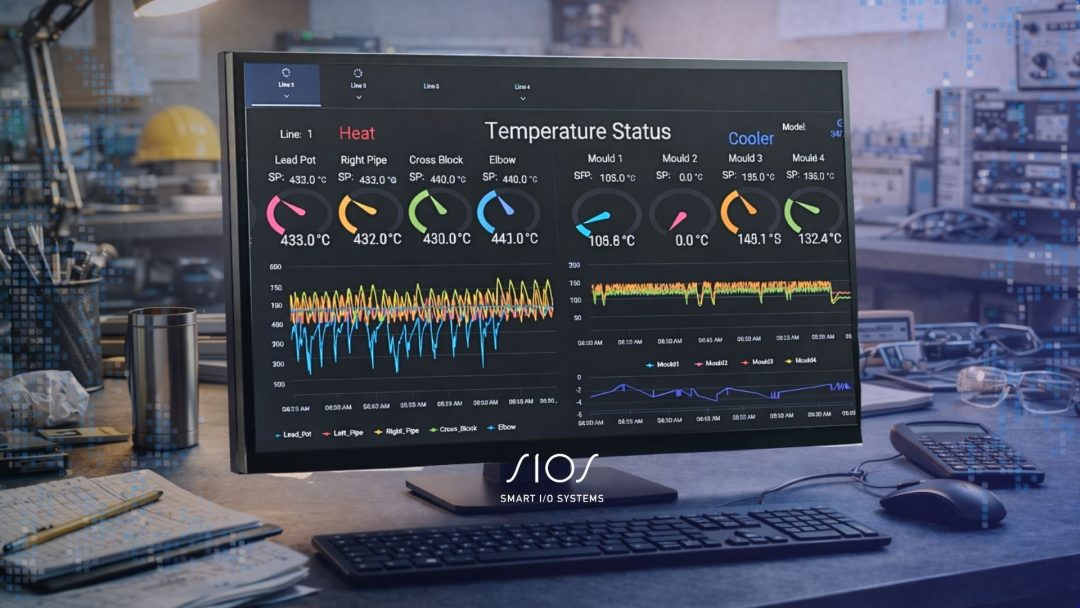

Additionally, real-time monitoring of critical process variables was enabled, such as temperatures in key system components, including:

- Molten lead crucible

- Lead feed pipes

- Lead distribution block

- Molds and cooling system

All this information was presented through intuitive dashboards, accessible from local and remote devices.

Benefits

Implementing this solution allowed the client to:

- Gain complete operational visibility of all their production lines

- Objectively compare performance between lines

- Reduce report generation time

- Improve data-driven decision-making

- Maintain compliance with IT security policies

- Scale the solution without impacting existing operations

- The system was ready to integrate with production, maintenance, and management areas, facilitating a more efficient and transparent operation.